Important Tools and Strategies for Efficient Lead Violation Cleaning

Dealing with lead offenses successfully demands an extensive strategy that blends the right devices with strategic techniques. Concurrently, the usage of specialized cleaning tools, such as HEPA vacuums and lead-specific cleansing representatives, is important for detailed contaminant elimination. Reliable control methods, including plastic sheeting and unfavorable air stress systems, are essential to avoid the spread of unsafe products.

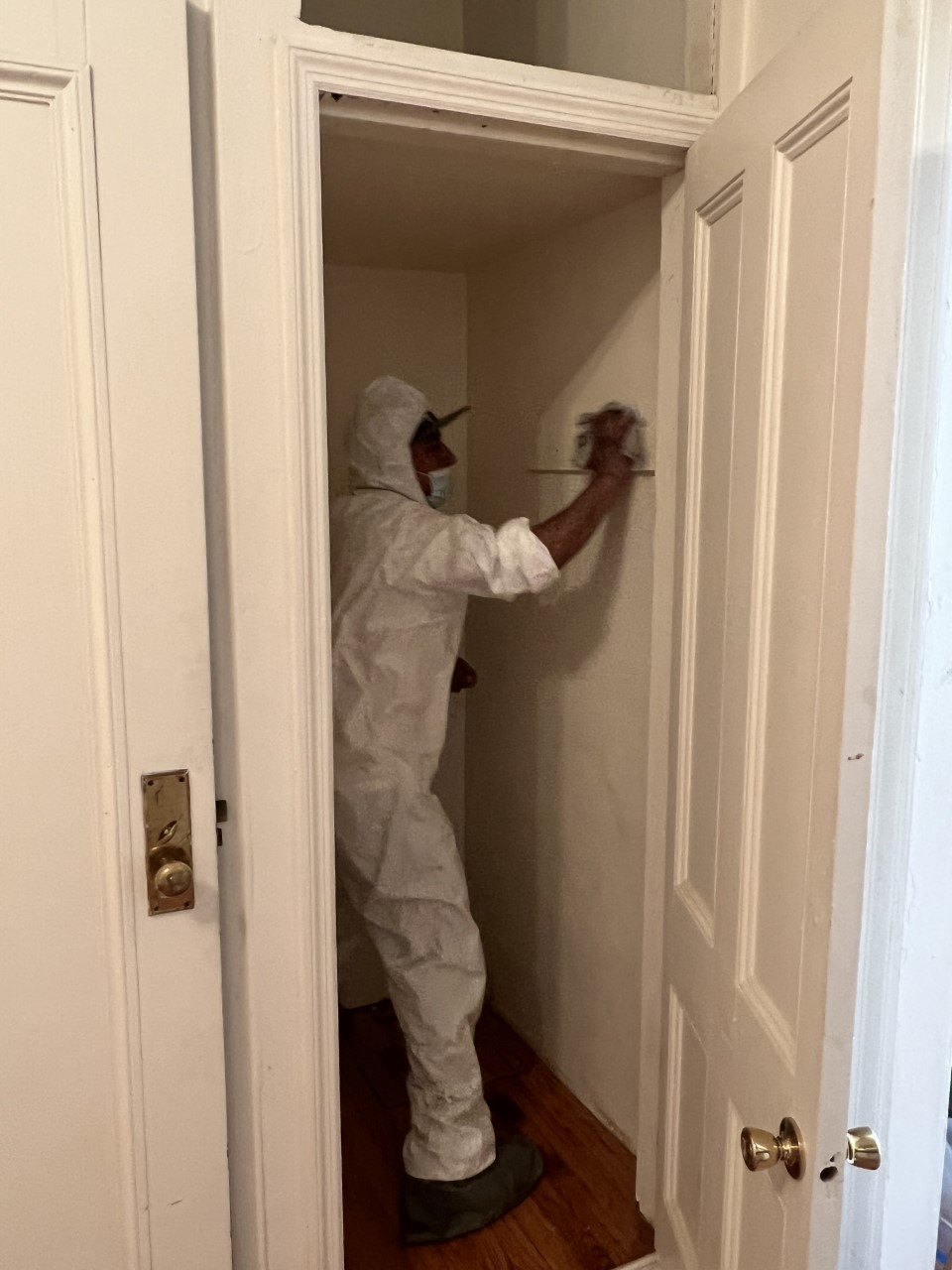

Personal Protective Tools

Personal protective devices (PPE) is a critical component in the effective administration of lead contamination clean-up. PPE functions as an essential barrier, protecting workers from the dangerous impacts of lead direct exposure, which can result in extreme health and wellness effects. The important PPE for lead cleanup includes respirators, protective clothing, gloves, and eye security. Each type of devices is particularly developed to alleviate various risks related to lead particles and dust.

Respirators, particularly those equipped with HEPA filters, are crucial for filtering air-borne lead bits, preventing inhalation. Safety clothes, consisting of coveralls and non reusable suits, prevents lead dirt from adhering to employees' garments, decreasing the threat of additional contamination.

Moreover, strenuous training on the right usage and maintenance of PPE is crucial. Workers should be enlightened on donning and doffing treatments to avoid contamination. Routine assessments and substitutes of PPE elements are essential to maintain their safety abilities, ensuring a risk-free and certified cleanup procedure.

Specialized Cleaning Tools

Another necessary device is the wet/dry vacuum, which can efficiently cleanse up both dirt and liquid pollutants. These vacuum cleaners typically include HEPA filters to give an additional layer of security. Damp cleans or tack cloths are likewise critical for surface cleaning; they are particularly made to capture and hold lead particles, decreasing the danger of spreading contamination.

For even more persistent down payments, specialized lead-removal cleaner are called for. These agents are formulated to damage down lead particles, making them simpler to eliminate. Scrub brushes with strong bristles can help in this procedure, specifically on harsh surface areas where lead dust has a tendency to adhere much more strongly.

Furthermore, encapsulants are used to seal lead-contaminated surfaces, stopping the release of lead dust. These specialized paints and finishes are created to follow different substrates, supplying a long-lasting option for lead containment.

Efficient Containment Methods

Effective control approaches are critical in minimizing the spread of lead contamination throughout clean-up activities. Executing robust control strategies ensures that lead fragments do not move to unaffected areas, thereby shielding both workers and the environment. One primary approach is the usage of plastic sheet to seal off infected areas. Sturdy polyethylene obstacles can be set up from floor to ceiling to develop a controlled workspace, substantially minimizing the danger of airborne lead dirt dispersal.

To enhance containment, encapsulants can be put on surface areas that are not being removed or interrupted. These specialized finishings bind lead dirt, minimizing its availability for resuspension. In addition, all workers have to wear suitable Individual Protective Tools (PPE), including respirators and non reusable fits, to stop contamination spread.

Safe Disposal Practices

Making certain safe disposal techniques is a vital component in the administration of lead contamination clean-up. Proper disposal alleviates the threat of lead re-entering the atmosphere and jeopardizing public health. The initial step is to recognize and segregate lead-contaminated waste from other products. Secure containment utilizing sturdy, check my reference leak-proof containers is important to stop splilling throughout transport.

Carrying lead waste calls for adherence to strict guidelines. Using certified contaminated materials providers makes sure that the products are handled properly. Paperwork, including materializes outlining the type and quantity of waste, ought to come with shipments to track the waste from the site of origin to article source its last disposal location.

Designated contaminated materials disposal centers are outfitted to take care of lead-contaminated materials safely. These facilities often employ innovative approaches such as stablizing, solidification, or chemical therapy to reduce the effects of the lead prior to disposal. Landfilling in specialized, lined locations that stop leachate from polluting groundwater is a typical practice for final disposal.

Normal training for employees included in lead waste disposal is important to maintain safety and security criteria and stop unintentional exposure. By sticking to these techniques, companies can dramatically minimize the environmental and health and wellness influences connected with lead contamination.

Regulatory Compliance Tips

Sticking to regulatory conformity is critical in the effective execution of lead contamination cleaning. Comprehending and following federal, state, and regional regulations makes certain not only the safety and security and health of people but additionally the legal and monetary well-being of the clean-up organization. The Epa (EPA) sets rigorous requirements, such as the Lead Restoration, Repair Work, and Paint (RRP) Rule, which mandates appropriate certification and training for specialists handling lead-based activities.

Compliance begins with a detailed assessment of appropriate legislations and guidelines. Organizations has to remain upgraded on any kind of legislative changes, which can be promoted through regular training sessions and subscribing to market updates. Paperwork is one more essential conformity facet; maintaining detailed records of all activities, check this site out including examination records, staff member training logs, and disposal manifests, is essential.

Furthermore, engaging with certified lead inspectors or risk assessors guarantees that lead dangers are properly determined and reduced. Employers should impose making use of Individual Safety Tools (PPE) and ensure that safety methods are purely complied with. Clear communication with stakeholders, including staff members, customers, and regulative bodies, will cultivate a society of compliance and liability, eventually contributing to a more secure and more reliable lead clean-up process.

Verdict

Efficient lead infraction cleanup demands the integration of specialized tools and critical methodologies to make sure security and efficiency. Individual protective devices (PPE) safeguards employees from direct exposure, while secure disposal practices and stringent adherence to regulative compliance are necessary for sensibly managing dangerous waste.